YES! WE ARE ROCKET SCIENCE!

- MicroGuard’s coatings and surface treatments have their origins in NASA research. Dr. John B. Schutt, a theoretical chemist and former head of coatings for NASA, developed inorganic coatings for rockets and space vehicles to control corrosion caused by extreme UV radiation, rocket exhaust gases, chemical contaminants, and were required to withstand excessive temperature fluctuations.

- Following his retirement from NASA in 1991, Dr. Schutt began additional work on developing a range of pre-ceramic, clear coatings that cure at ambient temperatures. These coatings were hybrids of his previous work, resulting in the next generation of Patented inorganic, siloxane coatings – MicroGuard Coatings.

- For his work with NASA, Dr. Schutt was inducted into the NASA Inventor’s Hall of Fame in 1995.

- Hardness

- Repellant

- Antimicrobial

- Durability

- Wear Resistance

- Chemical Resistance

WHAT MAKES US DIFFERENT

SUMMARY OF BENEFITS

- Sustainable / ROI average at 18 months

- Reduction in Cleaning Materials

- Reduction In Labor Costs

- No Maintenance Contract necessary

- Stain Proof, No Buffing, Water or Neutral pH Cleaner Only

- Patented Product – No Real Competition

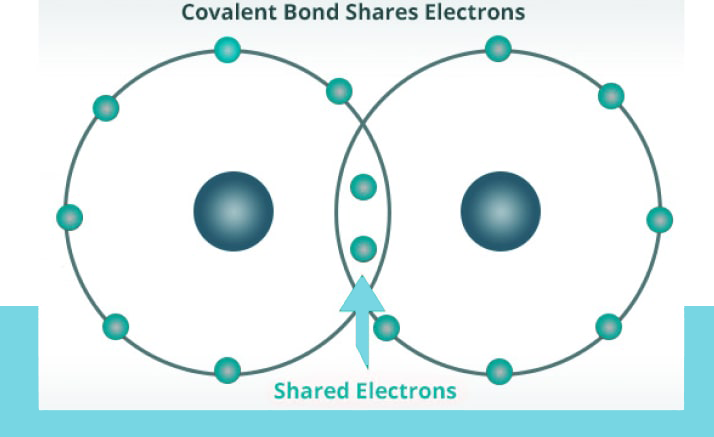

- Covalent Bond

- Rated High Traction by NFSI

- 30-40% Higher than NFSI Standards

- Extreme Durability – ASTM D4060

- Anti-Fungal / Microbial Performance

- ASTM G21 – Rated ‘0’ Due to No Growth

- High Gloss or Matte Finish

- Chemical Resistant

- Anti-Graffiti (non-sacrificial)

- Protects Non-Ferrous Metals Against Corrosion

- Protects Painted Metal Surfaces Against Corrosion and Wear

- Coats Multiple Hard Surfaces

- Brings Colors Back to Life

- Indoor and Outdoor

- Hot & Cold Extreme Tolerance

PRODUCT BENEFITS

The National Floor Safety Institute – B101.1 Safety Standard

NFSI’s approach to slip-and-fall prevention was different from what was previously employed. Because approximately 80 percent of all slip-and-fall accidents occur on wet walkways. So rather than simply categorizing walkways as safe or unsafe based upon a single COF value, the ANSI/NFSI B101.1-2009 standard identifies three individual risk categories, or “Traction Ranges.”

NFSI found that walkways whose wet SCOF was 0.60 or greater reduced slip-and-fall claims by as much as 90 percent and are defined by the B101.1 standard as “High Traction.” Adsil MicroGuard is officially certified by the NFSI as providing “High Traction.”

MICROGUARD CUSTOMERS

The National Floor Safety Institute – B101.1 Safety Standard

NFSI’s approach to slip-and-fall prevention was different from what was previously employed. Because approximately 80 percent of all slip-and-fall accidents occur on wet walkways. So rather than simply categorizing walkways as safe or unsafe based upon a single COF value, the ANSI/NFSI B101.1-2009 standard identifies three individual risk categories, or “Traction Ranges.”

NFSI found that walkways whose wet SCOF was 0.60 or greater reduced slip-and-fall claims by as much as 90 percent and are defined by the B101.1 standard as “High Traction.” Adsil MicroGuard is officially certified by the NFSI as providing “High Traction.”

SIDE BY SIDE COMPARISONS

[wplg_gallery gallery_id=”103″]